Non-destructive testing (NDT) techniques have developed as important instruments in the evaluation of concrete structures, providing a way to analyze structural integrity and material qualities without causing damage. In analyzing the uniformity, homogeneity, approximate compressive strength, durability, the level of rebar corrosion in concrete, and other properties of damaged buildings, NDT technologies have a significant benefit. This paper offers a thorough examination of several NDT methods, emphasizing their usefulness in finding internal flaws, locating embedded items, and measuring surface-hardness and in-situ stress. Each method's applicability, limitations, and measured parameters are thoroughly addressed. The criteria for selecting appropriate NDT methods are discussed, followed by a comparison of different approaches to facilitate decision-making. The interpretation of NDT results is discussed, highlighting the significance of precise data processing and the relevance of sophisticated technology. Case studies were also provided to demonstrate the actual implementation and efficacy of NDT techniques in real-world circumstances. The assessment also suggests investing in advanced data visualization tools to better the interpretation and sharing of NDT results, as well as combining NDT data with Building Information Modeling systems to provide a more complete picture of structural problems. Finally, the paper indicates that NDT techniques are critical for assuring the safety, durability, and preservation of concrete structures, thereby significantly contributing to the upkeep of our built environment.

| Published in | American Journal of Civil Engineering (Volume 13, Issue 1) |

| DOI | 10.11648/j.ajce.20251301.12 |

| Page(s) | 10-31 |

| Creative Commons |

This is an Open Access article, distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution and reproduction in any medium or format, provided the original work is properly cited. |

| Copyright |

Copyright © The Author(s), 2025. Published by Science Publishing Group |

Flaws, NDT, In-situ Stress, Surface-Hardness

NO. | NDT METHOD | INTERNATIONAL STANDARDS AND CODE |

|---|---|---|

1. | Schmidt Rebound Hammer test | ASTM C805/C805M; BS EN 13791:2019; BS 1881-202: 1986; ASTM D5873-14 |

2. | Penetration Resistance | ASTM C 803-82/C803M; BS 1881 - 207 |

3. | Pull-Off testing | ASTM C1583/C1583M; BS EN 1542 |

5. | Ground Penetrating Radar (GPR) | ASTM D6087-08; ASTM D6432-11; BS EN 302 066 V2.2.1 |

6. | Half-Cell Potential | ASTM C876-91; BS 1881-201 |

7. | Radiographic Testing | BS 1881-205; ASTM E1742/E1742M-18; BS 4408-3; ASTM E94/E94M-17; ISO 19232-1:2013 |

8. | Ultrasonic Pulse Velocity (UPV) | ASTM C597-97; BS 1881-203: 1986; BS 4408-5:1974; BS EN 12504-4: 2021; ISO/DIS 8047 |

9. | Acoustic Emission | ASTM E2983-14:2019; ASTM E3100-17 ISO 16836:2019 |

10. | Impact –echo test | ASTM C1383-23; ACI 228.2R |

11. | Laser Scanning | ASTM E3022; ISO 16331-1; BS 1192-4 |

12. | Infrared Thermography | ASTM D4788-88; ASTM C1060-11a ISO 6781-1:2023 |

13. | Visual Inspection | ASTM C823/C823M-12:2017; ACI PRC-201.1-08 |

14. | Electrical Resistivity | ASTM C1760-12; UNE 83988-1 & 2 |

15. | Vibration-based methods | ASTM C215-19; BS 1881-209:1990 |

16 | Computer tomography | ASTM E1441; ISO 15708-1, 2 &3 |

No | NDT Methods | Parameter | Application | Limitation |

|---|---|---|---|---|

1. | Schmidt Rebound Hammer test [7, 9, 33, 34, 38-41] | Surface hardness Compressive strength Uniformity of concrete | To estimate strength and assess uniformity of concrete to assure quality To estimate early edge strength rate of strength gain for construction scheduling | Surface condition affect results significantly Measures limited depth (20-30 mm) Not suitable for concrete strength beyond 60 MPa and lightweight concrete with density less than 1440 kg/m3 Difficulty to assess internal flaws |

2. | Penetration Resistance (Windsor Probe) [42, 43] | Compressive strength Surface hardness Material uniformity | To estimate strength in place to ensure safety and durability of concrete The test was also applicable to evaluate lightweight concrete strength | The concrete thickness should be three times depth of probe penetration The test location must be away from Edge and rebar proximity Not suitable for concrete strength beyond 40 MPa Minimal hole left in concrete surface Difficulty to assess internal flaws |

3. | Pull-Off testing [44-48] | Bond strength | To assess the adhesion strength of coating applied to flooring system and exterior coating and cladding systems to building facades Verifying the adhesion of waterproofing membranes and protective coatings on steel structures. | Affected greatly by surface preparation (surface cleanness, free of dirty and roughness) The test is partially destructive Temperature and humidity affect results moderately Require operator skills |

4. | Ground Penetrating Radar (GPR) [10, 49-52] | Thickness measurement Void and crack detection Depth and position of rebar | Determine rebar formation and corrosion mapping within concrete structures Describing the thickness of concrete slabs and walls to ensure design specification Detect concrete deterioration and delamination | Resolution trade-off at dense materials making difficult to detect internals In heavily RC closely spaced bar (less than 7 cm) create signal clutter highly Surface condition (uneven or coating) can affect results Moisture content in concrete can affect accuracy of GPR |

5. | Half-cell potential [35, 36, 53-56] | Corrosion potential Probability of corrosion Corrosion mapping | For assessment of the durability of reinforced concrete members where reinforcement corrosion is suspected. | Requires direct access to the concrete surfaces, which can be challenging in certain structures. Moisture content, temperatures and too thickness of concrete cover affect results Surface coating or overlays affect result greatly Provides a probability of corrosion rather than definitive measure Result interpreting requires experience and understanding of specific condition. |

6. | Radiographic Testing [57-61] | Internal defects Thickness variation Density difference Reinforcement detail Structural integrity | To estimate bar size and location within concrete Detect concrete deterioration and delamination To control quality of materials and component meets specified standards | The ability of portable X-ray units penetration depth is limited up to 20 cm Requires strict safety measures Expensive and slower compared The setup and execution of radiography testing are complex The cost are relatively high |

7. | Ultrasonic Pulse Velocity (UPV) [31, 32, 62-66] | Uniformity and density Compressive strength Depth of surface-breaking cracks | Evaluate quality and uniformity Detect internal flaws To predict concrete strength Detection of damage in concrete and to monitor structural health | Surface condition affect results significantly Moisture condition affect greatly For accuracy access to both sides of structures is often required Difficult to detect fine cracks Material heterogeneity can cause fluctuations in consistent reading They are less effective detecting defects beyond 50 cm in concrete |

8. | Acoustic Emission [70-78] | Nature and Level of damage Damage mechanism Location of damage | To detect and locate damage Corrosion monitoring in RC To control quality of concrete Continuously to monitor structures | It requires good surface access to place sensor (rough surface hinder success) Environmental interference reduce reliability of test by up to 20-30% AE testing is more effective at detecting active defects that are growing Limited to detection range from sensor |

9. | Impact–echo test [11, 37, 67-69] | Thickness Internal defects Characteristic of defect Mechanical properties | To assess delamination and voids To measure thickness and depth To detect and assessing the depth and extent of cracks To assess mechanical properties of concrete | Effective for limited depth (1 m) in concrete Surface condition can lead to poor signal Material heterogeneity within the concrete structure can scatter waves Environmental noise and operational vibration can interface IE signals |

10. | Laser Scanning [79-81] | Volume and area Alignment and tolerance Floor flatness and levelness Deformation and deflection | Dimensional analysis and tolerance checking Monitoring deformation and displacement To verify construction work | Requires clear access to the surface being scanned Reflective and transparent surfaces can distort the laser signals greatly Environmental condition reducing the accuracy and reliability High quality laser scanning equipment are expensive |

11. | Infrared Thermography [12, 84-89] | Surface temperature Moisture content Insulation quality Energy efficiency | To detect delamination and voids To detect moisture intrusion in structures evaluating the effectiveness of insulation by identifying areas of heat loss | Limited to detect near-surface Environmental sensitivity for ambient temperature, wind and sunlight Surface condition affects greatly the accuracy of readings Not effective for concrete due to low thermal conductivity Requires experienced experts |

12. | Visual Inspection [82, 83] | Surface condition Discoloration, efflorescence, spalling and staining Corrosion of reinforcement Joint condition Structural deformation | To gain information in construction methods and faults, weathering, chemical attack, visible mechanical damage and physical deterioration To evaluate overall structural condition To conduct routine safety inspection | Surface-only detection difficult to detect internal flaws Highly subjective and human factor Does not provides quantitative data’s about material properties like strength Very small defects may not be noticed Poor lighting, weather condition and accessibility can affect accuracy |

13. | Electrical Resistivity [90-96] | Pore structures Moisture content Chloride ion penetration Permeability | To assess durability BY measuring chloride ion penetration To measure the potential for corrosion in steels within concretes To measure the moisture content in concrete | Influenced by moisture content and temperatures in structures Affected results up to 30-40% by presence of aggregate and steel Surface condition can lead to errors by up to 20-30% It provides an resistivity values over the areas it can mask localized defects within the concrete |

14. | Vibration-based methods [97] | Natural frequencies Mode shapes Damping ratio Modal strain energy | To detect damage and dynamic property for structural health monitoring To assess the seismic performance of structure | Environmental sensitivity (traffic, wind and machinery) affected significantly Not more effective in detecting localized damage Requires accurate baseline measurements of the structures vibration characteristics Temperature affects slightly results |

15. | Strain sensing methods [98] | Axial and shear strain Crack width Temperature Pre-stressing force | To detect early structural issues (cracks or deformation) To evaluate the performance and load bearing capacity of structures To monitor fatigue and seismic in structures | Temperature variation affects reading by up to 10-15% High quality strains sensors significantly more expensive Over time sensor degradation lead to gradual decrease in accuracy Installation challenge lead to errors as much as 5-15% |

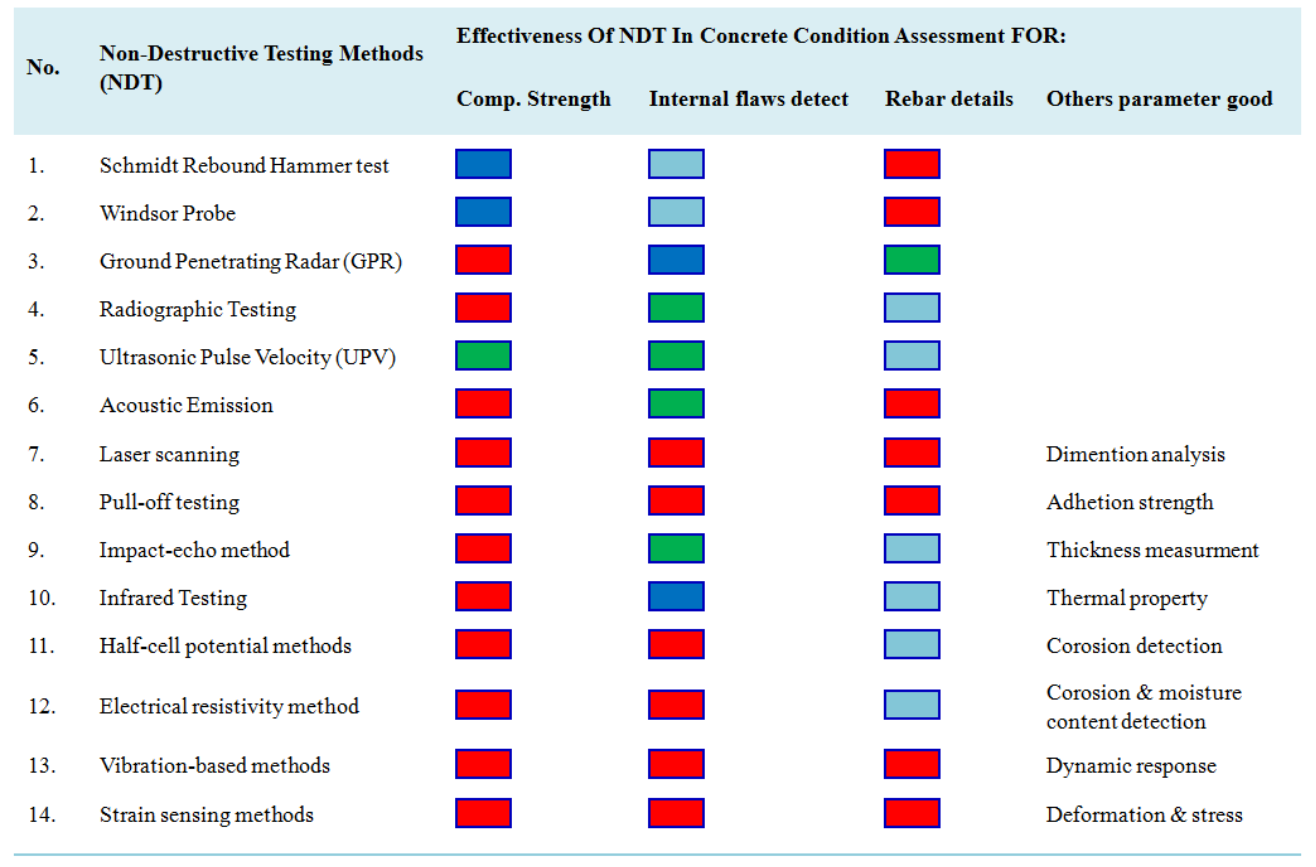

: Excellent

: Excellent  : Good

: Good  : Limited

: Limited  : Not-valid

: Not-valid NDT Method | Results | Interpreting NDT output | |

|---|---|---|---|

1. | Schmidt Rebound Hammer test | Rebound number | Each hammer comes with a coversion chart that translate rebound nuber into estimated compressive strength. |

2. | Ground Penetrating Radar | Radargram | The radagram displays the refelected signals. The key aspect to interpre include: 1) Hyperbola: indicate the presence of discrtet objects like rebar or voids. 2) Continous Line: shows layer interferance or chnage in material properties 3) Signal Amplitude: strong reflected signal indicates density and uniformity |

3. | Radiographic Testing | Radiographic Image | The radiographic image are examined and the key aspect to interpre include: 1) Dark areas: Indicate less dense regions, the presence of internal flaws 2) Light areas: Suggest sound materials absorb more radiation 3) Sharp edge: specify the presence of cracks or sharp discontinuities 4) Blurry areas: Suggest gradual change in material density, such as porosity |

4. | Ultrasonic Pulse Velocity | Velocity | The primary output is pulse velocity, calculated using; (L is distance between transducers; T is time travel of ultrasonic pulse). The values interpreted as: below 3 km/s (Doubtful quality); 3.0 to 3.5 km/s (Medium quality); 3.5 to 4.5 km/s (Good quality); above 4.5 km/s (Excellent quality). The empirical relationship is established between pulse velocity and compressive strength of concrete using regression analysis. Graphs showing the arrivals time and amplitude of the ultrasonic waves. The amplitude of the wave provide about the materials properties. |

5. | Impact-echo method | Time-domain waveform | The raw data is transformed into frequency domain using Fast Fourier transform (FFT). The primary peak in the frequency spectrum corresponds to the thickness of concrete or flaws depth. Higher frequency indicate shallower defects while low frequency indicate deeper defects. |

6. | Infrared Testing | Thermal image | Thermal images displays tempreture variations using color maps. Different colors represents different tempreture, Blue and purple (Cool ares indicate sound materials or areas without defects, Green (Room tempreture indicate normal condition without significat defects), Yellow and orange (Warm areas suggest voids, delamination or moisture), Red: (higher tempreture suggest significant defects) and White (hottest area suggest sever defects) |

7. | Electrical resistivity method | Resistivity value | High resistivity >20 kΩ-cm: [Indicates low permeability and high durability] Moderate Resistivity 10-20 kΩ-cm: [Indicates moderate permeability and durability] Low resistivity <10 kΩ-cm: [Indicates high permeability and low durability] |

AREA OF DEFECTS | Number Of Pixels | IR Measurement Of Area | Percentage Of Accuracy | |

|---|---|---|---|---|

1. | Actual Area Of Defects | 30276 | 9 cm2 | 100% |

2. | The 5 mm Deep Defect | 21286 | 6.33 cm2 |

|

3. | The 10 mm Deep Defect | 5727 | 1.7 cm2 |

|

Results | Correlation | No. of used data (n) | R2 | Standard Error | |

|---|---|---|---|---|---|

1. | Schmidt Rebound Hammer (SRH) |

| 18 | 93.6% | 2.1024 |

2. | Ultrasonic Pulse Velocity (UPV) |

V is ultrasonic pulse velocity. | 18 | 91.9% | 3.3746 |

3. | SonReb |

| 18 | 95% | 1.8491 |

ACI | American Concrete Institute |

AI | Artificial Intelligence |

ASTM | American Society for Testing and Materials |

BIM | Building Information Modelling |

BS | British Standard |

EDS | Energy Dispersive Spectroscopy |

FFT | Fast Fourier Transform |

GFRP | Glass Fiber Reinforced Polymer |

GPR | Ground-Penetrating Standard |

ISO | International for Standardization |

IRT | Infrared Thermography |

ML | Machine Learning |

NDT | Nondestructive Testing |

QC | Quality Control |

QA | Quality Assurance |

RC | Reinforced Concrete |

RCC | Reinforced Cement Concrete |

SFRC | Steel Fiber Reinforced Concrete |

SHM | Structural Health Monitoring |

SRH | Schmidt Rebound Hammer |

UAV | Unmanned Aerial Vehicle |

UPV | Ultrasonic Pulse Velocity |

| [1] | Atici, U., Prediction of the strength of mineral admixture concrete using multivariable regression analysis and an artificial neural network. Expert Systems with applications, 2011. 38(8): p. 9609-9618. |

| [2] | Bilgehan, M. and P. Turgut, Artificial neural network approach to predict compressive strength of concrete through ultrasonic pulse velocity. Research in Nondestructive Evaluation, 2010. 21(1): p. 1-17. |

| [3] | Brencich, A., et al., Calibration and reliability of the rebound (Schmidt) hammer test. Civil Engineering and Architecture, 2013. 1(3): p. 66-78. |

| [4] | Mohammed, B. S., N. J. Azmi, and M. Abdullahi, Evaluation of rubbercrete based on ultrasonic pulse velocity and rebound hammer tests. Construction and Building Materials, 2011. 25(3): p. 1388-1397. |

| [5] | Mohammed, T. U. and M. N. Rahman, Effect of types of aggregate and sand-to-aggregate volume ratio on UPV in concrete. Construction and Building Materials, 2016. 125: p. 832-841. |

| [6] | Pucinotti, R., Reinforced concrete structure: Non destructive in situ strength assessment of concrete. Construction and Building Materials, 2015. 75: p. 331-341. |

| [7] | Shariati, M., et al., Assessing the strength of reinforced concrete structures through Ultrasonic Pulse Velocity and Schmidt Rebound Hammer tests. scientific research and essays, 2011. 6(1): p. 213-220. |

| [8] | Szilágyi, K., A. Borosnyói, and I. Zsigovics, Understanding the rebound surface hardness of concrete. Journal of Civil Engineering and Management, 2015. 21(2): p. 185-192. |

| [9] | Kazemi, M., R. Madandoust, and J. de Brito, Compressive strength assessment of recycled aggregate concrete using Schmidt rebound hammer and core testing. Construction and Building Materials, 2019. 224: p. 630-638. |

| [10] | Alani, A. M., M. Aboutalebi, and G. Kilic, Applications of ground penetrating radar (GPR) in bridge deck monitoring and assessment. Journal of applied geophysics, 2013. 97: p. 45-54. |

| [11] | Krzemień, K. and I. Hager, Post-fire assessment of mechanical properties of concrete with the use of the impact-echo method. Construction and Building Materials, 2015. 96: p. 155-163. |

| [12] | Lu, Y., A. J. Golrokh, and M. A. Islam, Concrete pavement service condition assessment using infrared thermography. Advances in Materials Science and Engineering, 2017. 2017(1): p. 3829340. |

| [13] | ASTM, Standard test method for compressive strength of cylindrical concrete specimens. ASTM international, 2014. |

| [14] | Gupta, M., et al., Advances in applications of Non-Destructive Testing (NDT): A review. Advances in Materials and Processing Technologies, 2022. 8(2): p. 2286-2307. |

| [15] | Amini, K., et al., Development of prediction models for mechanical properties and durability of concrete using combined nondestructive tests. Journal of Materials in Civil Engineering, 2019. 31(2): p. 04018378. |

| [16] | Kouddane, B., et al., Assessment of concrete strength using the combination of NDT—review and performance analysis. Applied Sciences, 2022. 12(23): p. 12190. |

| [17] | Giannini, R., et al., Assessment of concrete strength combining direct and NDT measures via Bayesian inference. Engineering structures, 2014. 64: p. 68-77. |

| [18] | Prassianakis, I. and P. Giokas, Mechanical properties of old concrete using destructive and ultrasonic non-destructive testing methods. Magazine of Concrete Research, 2003. 55(2): p. 171-176. |

| [19] | Rajabi, A. M., F. Omidi Moaf, and H. S. Abdelgader, Evaluation of mechanical properties of two-stage concrete and conventional concrete using nondestructive tests. Journal of Materials in Civil Engineering, 2020. 32(7): p. 04020185. |

| [20] | Aghaee, K., M. A. Yazdi, and K. D. Tsavdaridis, Investigation into the mechanical properties of structural lightweight concrete reinforced with waste steel wires. Magazine of Concrete research, 2015. 67(4): p. 197-205. |

| [21] | Esteves, I. C., R. A. Medeiros-Junior, and M. H. Medeiros, NDT for bridges durability assessment on urban-industrial environment in Brazil. International Journal of Building Pathology and Adaptation, 2018. 36(5): p. 500-515. |

| [22] | Hoła, J., J. Bień, and K. Schabowicz, Non-destructive and semi-destructive diagnostics of concrete structures in assessment of their durability. Bulletin of the Polish Academy of Sciences. Technical Sciences, 2015. 63(1): p. 87--96. |

| [23] | Glavaš, H., et al., Locating hidden elements in walls of cultural heritage buildings by using infrared thermography. Buildings, 2019. 9(2): p. 32. |

| [24] | Hussain, A. and S. Akhtar, Review of non-destructive tests for evaluation of historic masonry and concrete structures. Arabian Journal for Science and Engineering, 2017. 42(3): p. 925-940. |

| [25] | Forde, M. C., International practice using NDE for the inspection of concrete and masonry arch bridges. Bridge Structures, 2010. 6(1, 2): p. 25-34. |

| [26] | Saremi, S. G., D. G. Goulias, and A. A. Akhter, Non-destructive testing in quality assurance of concrete for assessing production uniformity. Transportation Research Record, 2023. 2677(1): p. 1259-1275. |

| [27] | Kim, M. -K., H. Sohn, and C. -C. Chang, Automated dimensional quality assessment of precast concrete panels using terrestrial laser scanning. Automation in Construction, 2014. 45: p. 163-177. |

| [28] | Verma, S. K., S. S. Bhadauria, and S. Akhtar, Review of nondestructive testing methods for condition monitoring of concrete structures. Journal of construction engineering, 2013. 2013(1): p. 834572. |

| [29] | Xiong, C., J. Yu, and X. Zhang, Use of NDT systems to investigate pavement reconstruction needs and improve maintenance treatment decision-making. International Journal of Pavement Engineering, 2023. 24(1): p. 2011872. |

| [30] | Kot, P., et al., Recent advancements in non-destructive testing techniques for structural health monitoring. Applied Sciences, 2021. 11(6): p. 2750. |

| [31] | Mata, R., R. O. Ruiz, and E. Nuñez, Correlation between compressive strength of concrete and ultrasonic pulse velocity: A case of study and a new correlation method. Construction and Building Materials, 2023. 369: p. 130569. |

| [32] | Yang, H., et al., Evaluating residual compressive strength of concrete at elevated temperatures using ultrasonic pulse velocity. Fire safety journal, 2009. 44(1): p. 121-130. |

| [33] | Bonagura, M. and L. Nobile, Artificial neural network (ANN) approach for predicting concrete compressive strength by SonReb. Struct. Durab. Health Monit, 2021. 15: p. 125-137. |

| [34] | Breccolotti, M. and M. F. Bonfigli, I-SonReb: an improved NDT method to evaluate the in situ strength of carbonated concrete. Nondestructive Testing and Evaluation, 2015. 30(4): p. 327-346. |

| [35] | Lai, W. -L., et al., Measurement of accelerated steel corrosion in concrete using ground-penetrating radar and a modified half-cell potential method. Journal of Infrastructure Systems, 2013. 19(2): p. 205-220. |

| [36] | Rhazi, J., et al. Non destructive health evaluation of concrete bridge decks by GPR and half cell potential techniques. in International Symposium on Non-Destructive Testing in Civil Engineering. 2003. |

| [37] | Zhang, J. -K., W. Yan, and D. -M. Cui, Concrete condition assessment using impact-echo method and extreme learning machines. Sensors, 2016. 16(4): p. 447. |

| [38] | Sanchez, K. and N. Tarranza, Reliability of rebound hammer test in concrete compressive strength estimation. Int. J. Adv. Agric. Environ. Eng, 2014. 1(2): p. 198-202. |

| [39] | Brencich, A., et al., Rebound hammer test: an investigation into its reliability in applications on concrete structures. Advances in Materials Science and Engineering, 2020. 2020(1): p. 6450183. |

| [40] | Brencich, A., et al., Compressive strength of solid clay brickwork of masonry bridges: Estimate through Schmidt Hammer tests. Construction and Building Materials, 2021. 306: p. 124494. |

| [41] | Balla, B., Z. Orbán, and A. Len, Assessing the reliability of single and combined diagnostic tools for testing the mechanical properties of historic masonry structures. Pollack Periodica, 2019. 14(3): p. 31-42. |

| [42] | Alyamac, K. E., et al. Estimation of concrete strength combining rebound hammer and Windsor probe test methods. in Proc., 4th Conf. Smart Monitoring, Assessment and Rehabilitation of Civil Structures. Zurich, Switzerland: International Society for Structural Health Monitoring of Intelligent Infrastructure. 2017. |

| [43] | Kog, Y. C., Estimating in situ compressive strength of existing concrete structures. Practice Periodical on Structural Design and Construction, 2018. 23(3): p. 04018013. |

| [44] | Fazli, H., et al., Pull-off testing as an interfacial bond strength assessment of CFRP-concrete interface exposed to a marine environment. International Journal of Adhesion and Adhesives, 2018. 84: p. 335-342. |

| [45] | Ramos, N., et al., Reliability of the pull-off test for in situ evaluation of adhesion strength. Construction and Building Materials, 2012. 31: p. 86-93. |

| [46] | Bonaldo, E., J. A. Barros, and P. B. Lourenço, Bond characterization between concrete substrate and repairing SFRC using pull-off testing. International journal of adhesion and adhesives, 2005. 25(6): p. 463-474. |

| [47] | Sadowski, Ł., Non-destructive identification of pull-off adhesion between concrete layers. Automation in Construction, 2015. 57: p. 146-155. |

| [48] | Mazzuca, S., et al., Mechanical characterization of steel-reinforced grout for strengthening of existing masonry and concrete structures. Journal of Materials in Civil Engineering, 2019. 31(5): p. 04019037. |

| [49] | Solla, M., et al., Ground-penetrating radar for the structural evaluation of masonry bridges: Results and interpretational tools. Construction and Building Materials, 2012. 29: p. 458-465. |

| [50] | Lombardi, F., M. Lualdi, and E. Garavaglia, Masonry texture reconstruction for building seismic assessment: Practical evaluation and potentials of Ground Penetrating Radar methodology. Construction and Building Materials, 2021. 299: p. 124189. |

| [51] | Martini, R., et al., Advances on the use of non-destructive techniques for mechanical characterization of stone masonry: GPR and sonic tests. Procedia Structural Integrity, 2017. 5: p. 1108-1115. |

| [52] | Beben, D., A. Mordak, and W. Anigacz, Ground penetrating radar application to testing of reinforced concrete beams. Procedia Engineering, 2013. 65: p. 242-247. |

| [53] | Almashakbeh, Y., E. Saleh, and N. M. Al-Akhras, Evaluation of half-cell potential measurements for reinforced concrete corrosion. Coatings, 2022. 12(7): p. 975. |

| [54] | Kyung, J. W., et al., Practical use of half-cell potential method for NDE of corrosion of reinforced concrete structure. Key Engineering Materials, 2004. 270: p. 1638-1644. |

| [55] | Leelalerkiet, V., et al., Analysis of half-cell potential measurement for corrosion of reinforced concrete. Construction and Building Materials, 2004. 18(3): p. 155-162. |

| [56] | Kim, Y. Y., et al., Effect of cover depth, w/c ratio, and crack width on half cell potential in cracked concrete exposed to salt sprayed condition. Construction and Building Materials, 2014. 54: p. 636-645. |

| [57] | Kamal, A. and M. Boulfiza, Durability of GFRP rebars in simulated concrete solutions under accelerated aging conditions. Journal of Composites for Construction, 2011. 15(4): p. 473-481. |

| [58] | Zhang, P., et al., Neutron radiography, a powerful method to determine time-dependent moisture distributions in concrete. Nuclear Engineering and Design, 2011. 241(12): p. 4758-4766. |

| [59] | De Beer, F., J. Le Roux, and E. Kearsley, Testing the durability of concrete with neutron radiography. Nuclear Instruments and Methods in Physics Research Section A: Accelerators, Spectrometers, Detectors and Associated Equipment, 2005. 542(1-3): p. 226-231. |

| [60] | Pei, C., W. Wu, and M. Ueaska, Image enhancement for on-site X-ray nondestructive inspection of reinforced concrete structures. Journal of X-Ray Science and Technology, 2016. 24(6): p. 797-805. |

| [61] | Movafeghi, A., et al., Inspection and monitoring of concrete structures via radiography and weighted nuclear norm minimization method. Russian Journal of Nondestructive Testing, 2020. 56: p. 361-368. |

| [62] | Bogas, J. A., M. G. Gomes, and A. Gomes, Compressive strength evaluation of structural lightweight concrete by non-destructive ultrasonic pulse velocity method. Ultrasonics, 2013. 53(5): p. 962-972. |

| [63] | Lee, H., et al., Ultrasonic in-situ monitoring of setting process of high-performance concrete. Cement and Concrete Research, 2004. 34(4): p. 631-640. |

| [64] | Huang, Q., P. Gardoni, and S. Hurlebaus, Predicting Concrete Compressive Strength Using Ultrasonic Pulse Velocity and Rebound Number. ACI Materials Journal, 2011. 108(4). |

| [65] | Manning, E., L. F. Ramos, and F. M. Fernandes. Direct sonic and ultrasonic wave velocity in masonry under compressive stress. in 9th International Masonry Conference. 2014. |

| [66] | Valluzzi, M. R., et al., Calibration of sonic pulse velocity tests for detection of variable conditions in masonry walls. Construction and Building Materials, 2018. 192: p. 272-286. |

| [67] | Epasto, G., E. Proverbio, and V. Venturi, Evaluation of fire-damaged concrete using impact-echo method. Materials and structures, 2010. 43: p. 235-245. |

| [68] | Kachanov, V., et al., Measuring the Acoustic Characteristics of Compact Concrete Building Structures Using the Impact Echo Method. Russian Journal of Nondestructive Testing, 2022. 58(1): p. 1-9. |

| [69] | Sadri, A., Application of impact-echo technique in diagnoses and repair of stone masonry structures. NDT & E International, 2003. 36(4): p. 195-202. |

| [70] | Noorsuhada, M., An overview on fatigue damage assessment of reinforced concrete structures with the aid of acoustic emission technique. Construction and Building Materials, 2016. 112: p. 424-439. |

| [71] | Yuyama, S., et al., Evaluation of fatigue damage in reinforced concrete slab by acoustic emission. NDT & e International, 2001. 34(6): p. 381-387. |

| [72] | Elfergani, H. A., R. Pullin, and K. M. Holford, Damage assessment of corrosion in prestressed concrete by acoustic emission. Construction and Building Materials, 2013. 40: p. 925-933. |

| [73] | Behnia, A., H. K. Chai, and T. Shiotani, Advanced structural health monitoring of concrete structures with the aid of acoustic emission. Construction and building materials, 2014. 65: p. 282-302. |

| [74] | Tsangouri, E., et al., Structural health assessment of prefabricated concrete elements using Acoustic Emission: Towards an optimized damage sensing tool. Construction and Building Materials, 2019. 206: p. 261-269. |

| [75] | Carpinteri, A. and G. Lacidogna, Damage evaluation of three masonry towers by acoustic emission. Engineering structures, 2007. 29(7): p. 1569-1579. |

| [76] | Wu, Y., et al., Damage assessment of the in-service brick masonry structure using acoustic emission technique. Materials and Structures, 2020. 53: p. 1-10. |

| [77] | Wu, Y., et al., Damage monitoring of masonry structure under in-situ uniaxial compression test using acoustic emission parameters. Construction and Building Materials, 2019. 215: p. 812-822. |

| [78] | Invernizzi, S., G. Lacidogna, and A. Carpinteri, Numerical models for the assessment of historical masonry structures and materials, monitored by acoustic emission. Applied Sciences, 2016. 6(4): p. 102. |

| [79] | Yang, H., X. Xu, and I. Neumann, The benefit of 3D laser scanning technology in the generation and calibration of FEM models for health assessment of concrete structures. Sensors, 2014. 14(11): p. 21889-21904. |

| [80] | Law, D. W., D. Silcock, and L. Holden, Terrestrial laser scanner assessment of deteriorating concrete structures. Structural Control and Health Monitoring, 2018. 25(5): p. e2156. |

| [81] | Olsen, M. J., et al., Terrestrial laser scanning-based structural damage assessment. Journal of Computing in Civil Engineering, 2010. 24(3): p. 264-272. |

| [82] | Stewart, M. G., Reliability safety assessment of corroding reinforced concrete structures based on visual inspection information. ACI Structural Journal, 2010. 107(6): p. 671. |

| [83] | Patel, R. A., et al. Convolution Neural Network-Based Machine Learning Approach for Visual Inspection of Concrete Structures. in Proceedings of the 1st Conference of the European Association on Quality Control of Bridges and Structures: EUROSTRUCT 2021 1. 2022. Springer. |

| [84] | Cheng, C. -C., T. -M. Cheng, and C. -H. Chiang, Defect detection of concrete structures using both infrared thermography and elastic waves. Automation in Construction, 2008. 18(1): p. 87-92. |

| [85] | Sirca Jr, G. F. and H. Adeli, Infrared thermography for detecting defects in concrete structures. Journal of Civil Engineering and Management, 2018. 24(7): p. 508-515. |

| [86] | Omar, T. and M. L. Nehdi, Remote sensing of concrete bridge decks using unmanned aerial vehicle infrared thermography. Automation in Construction, 2017. 83: p. 360-371. |

| [87] | Tavukçuoğlu, A., S. Akevren, and E. Grinzato, In situ examination of structural cracks at historic masonry structures by quantitative infrared thermography and ultrasonic testing. Journal of Modern Optics, 2010. 57(18): p. 1779-1789. |

| [88] | Cascardi, A., et al., Thermography Investigation and Seismic Vulnerability Assessment of a Historical Vaulted Masonry Building. Heritage, 2022. 5(3): p. 2041-2061. |

| [89] | Avdelidis, N. and A. Moropoulou, Applications of infrared thermography for the investigation of historic structures. Journal of Cultural Heritage, 2004. 5(1): p. 119-127. |

| [90] | Lataste, J., et al., Electrical resistivity measurement applied to cracking assessment on reinforced concrete structures in civil engineering. Ndt & E International, 2003. 36(6): p. 383-394. |

| [91] | Ferreira, R. M. and S. Jalali, NDT measurements for the prediction of 28-day compressive strength. NDT & E International, 2010. 43(2): p. 55-61. |

| [92] | Lataste, J., M. Behloul, and D. Breysse, Characterisation of fibres distribution in a steel fibre reinforced concrete with electrical resistivity measurements. Ndt & E International, 2008. 41(8): p. 638-647. |

| [93] | Azarsa, P. and R. Gupta, Electrical resistivity of concrete for durability evaluation: a review. Advances in Materials Science and Engineering, 2017. 2017(1): p. 8453095. |

| [94] | Yousuf, F., X. Wei, and J. Zhou, Monitoring the setting and hardening behaviour of cement paste by electrical resistivity measurement. Construction and Building Materials, 2020. 252: p. 118941. |

| [95] | Araújo, C. C. and G. R. Meira, Correlation between concrete strength properties and surface electrical resistivity. Revista IBRACON de Estruturas e Materiais, 2021. 15(1): p. e15103. |

| [96] | Wang, Z., et al., Effect of moisture content on freeze–thaw behavior of cement paste by electrical resistance measurements. Journal of materials science, 2014. 49(12): p. 4305-4314. |

| [97] | Ubertini, F., et al., Natural frequencies identification of a reinforced concrete beam using carbon nanotube cement-based sensors. Engineering structures, 2014. 60: p. 265-275. |

| [98] | Henault, J. -M., et al., Quantitative strain measurement and crack detection in RC structures using a truly distributed fiber optic sensing system. Construction and Building Materials, 2012. 37: p. 916-923. |

| [99] | du Plessis, A. and W. P. Boshoff, A review of X-ray computed tomography of concrete and asphalt construction materials. Construction and Building Materials, 2019. 199: p. 637-651. |

| [100] | Balázs, G. L., É. Lublóy, and T. Földes, Evaluation of concrete elements with X-ray computed tomography. Journal of Materials in Civil Engineering, 2018. 30(9): p. 06018010. |

| [101] | Zielińska, M. and M. Rucka, Non-destructive assessment of masonry pillars using ultrasonic tomography. Materials, 2018. 11(12): p. 2543. |

| [102] | Stepinac, M., et al., Methods for the assessment of critical properties in existing masonry structures under seismic loads—the ARES project. Applied Sciences, 2020. 10(5): p. 1576. |

| [103] | Stepinac, M. and M. Gašparović, A review of emerging technologies for an assessment of safety and seismic vulnerability and damage detection of existing masonry structures. Applied Sciences, 2020. 10(15): p. 5060. |

| [104] | Agarwal, V., et al., Concrete structural health monitoring in nuclear power plants. 2017, Idaho National Lab. (INL), Idaho Falls, ID (United States). |

| [105] | Baduge, S. K., et al., Artificial intelligence and smart vision for building and construction 4. 0: Machine and deep learning methods and applications. Automation in Construction, 2022. 141: p. 104440. |

| [106] | Taheri, H., M. Gonzalez Bocanegra, and M. Taheri, Artificial intelligence, machine learning and smart technologies for nondestructive evaluation. Sensors, 2022. 22(11): p. 4055. |

| [107] | Rohani, M., M. Fan, and C. Yu, Advanced visualization and simulation techniques for modern construction management. Indoor and Built Environment, 2014. 23(5): p. 665-674. |

| [108] | Liu, J., et al., A survey of applications with combined BIM and 3D laser scanning in the life cycle of buildings. IEEE Journal of Selected Topics in Applied Earth Observations and Remote Sensing, 2021. 14: p. 5627-5637. |

| [109] | Sadhu, A., et al., A review of data management and visualization techniques for structural health monitoring using BIM and virtual or augmented reality. Journal of Structural Engineering, 2023. 149(1): p. 03122006. |

| [110] | Dobmann, G., et al., Development of automated non-destructive evaluation (NDE) systems for reinforced concrete structures and other applications, in Non-destructive evaluation of reinforced concrete structures. 2010, Elsevier. p. 30-62. |

| [111] | Feroz, S. and S. Abu Dabous, Uav-based remote sensing applications for bridge condition assessment. Remote Sensing, 2021. 13(9): p. 1809. |

APA Style

Tefera, B. B., Tarekegn, A. G. (2025). Non-Destructive Testing Techniques for Condition Assessment of Concrete Structures: A Review. American Journal of Civil Engineering, 13(1), 10-31. https://doi.org/10.11648/j.ajce.20251301.12

ACS Style

Tefera, B. B.; Tarekegn, A. G. Non-Destructive Testing Techniques for Condition Assessment of Concrete Structures: A Review. Am. J. Civ. Eng. 2025, 13(1), 10-31. doi: 10.11648/j.ajce.20251301.12

AMA Style

Tefera BB, Tarekegn AG. Non-Destructive Testing Techniques for Condition Assessment of Concrete Structures: A Review. Am J Civ Eng. 2025;13(1):10-31. doi: 10.11648/j.ajce.20251301.12

@article{10.11648/j.ajce.20251301.12,

author = {Belay Bayu Tefera and Abrham Gebre Tarekegn},

title = {Non-Destructive Testing Techniques for Condition Assessment of Concrete Structures: A Review

},

journal = {American Journal of Civil Engineering},

volume = {13},

number = {1},

pages = {10-31},

doi = {10.11648/j.ajce.20251301.12},

url = {https://doi.org/10.11648/j.ajce.20251301.12},

eprint = {https://article.sciencepublishinggroup.com/pdf/10.11648.j.ajce.20251301.12},

abstract = {Non-destructive testing (NDT) techniques have developed as important instruments in the evaluation of concrete structures, providing a way to analyze structural integrity and material qualities without causing damage. In analyzing the uniformity, homogeneity, approximate compressive strength, durability, the level of rebar corrosion in concrete, and other properties of damaged buildings, NDT technologies have a significant benefit. This paper offers a thorough examination of several NDT methods, emphasizing their usefulness in finding internal flaws, locating embedded items, and measuring surface-hardness and in-situ stress. Each method's applicability, limitations, and measured parameters are thoroughly addressed. The criteria for selecting appropriate NDT methods are discussed, followed by a comparison of different approaches to facilitate decision-making. The interpretation of NDT results is discussed, highlighting the significance of precise data processing and the relevance of sophisticated technology. Case studies were also provided to demonstrate the actual implementation and efficacy of NDT techniques in real-world circumstances. The assessment also suggests investing in advanced data visualization tools to better the interpretation and sharing of NDT results, as well as combining NDT data with Building Information Modeling systems to provide a more complete picture of structural problems. Finally, the paper indicates that NDT techniques are critical for assuring the safety, durability, and preservation of concrete structures, thereby significantly contributing to the upkeep of our built environment.

},

year = {2025}

}

TY - JOUR T1 - Non-Destructive Testing Techniques for Condition Assessment of Concrete Structures: A Review AU - Belay Bayu Tefera AU - Abrham Gebre Tarekegn Y1 - 2025/01/23 PY - 2025 N1 - https://doi.org/10.11648/j.ajce.20251301.12 DO - 10.11648/j.ajce.20251301.12 T2 - American Journal of Civil Engineering JF - American Journal of Civil Engineering JO - American Journal of Civil Engineering SP - 10 EP - 31 PB - Science Publishing Group SN - 2330-8737 UR - https://doi.org/10.11648/j.ajce.20251301.12 AB - Non-destructive testing (NDT) techniques have developed as important instruments in the evaluation of concrete structures, providing a way to analyze structural integrity and material qualities without causing damage. In analyzing the uniformity, homogeneity, approximate compressive strength, durability, the level of rebar corrosion in concrete, and other properties of damaged buildings, NDT technologies have a significant benefit. This paper offers a thorough examination of several NDT methods, emphasizing their usefulness in finding internal flaws, locating embedded items, and measuring surface-hardness and in-situ stress. Each method's applicability, limitations, and measured parameters are thoroughly addressed. The criteria for selecting appropriate NDT methods are discussed, followed by a comparison of different approaches to facilitate decision-making. The interpretation of NDT results is discussed, highlighting the significance of precise data processing and the relevance of sophisticated technology. Case studies were also provided to demonstrate the actual implementation and efficacy of NDT techniques in real-world circumstances. The assessment also suggests investing in advanced data visualization tools to better the interpretation and sharing of NDT results, as well as combining NDT data with Building Information Modeling systems to provide a more complete picture of structural problems. Finally, the paper indicates that NDT techniques are critical for assuring the safety, durability, and preservation of concrete structures, thereby significantly contributing to the upkeep of our built environment. VL - 13 IS - 1 ER -