The use of ethanol in diesel engines as an alternative to fossil fuels and air pollution prevention due to vehicle exhaust emissions has been investigated. It can be seen that for a more practical application of the performance study of diesel-ethanol dual fuel engine, the effect of ethanol on the performance at 100% load as well as at different load conditions should be considered. The effect of ethanol content on combustion and performance characteristics under different load conditions of diesel-ethanol dual-fuel engine was investigated using engine simulation tool. The engine model was constructed using the pre-combustion-diffusion combustion two phase combustion model of GT-POWER, and the simulation results of the main performance indices were compared with the test data. The effect of ethanol blending ratio on the performance of diesel-ethanol blend engine with varying ethanol content (0-20% ethanol) under different loading conditions (25-100% load) was investigated. As the load decreases, the effect of ethanol blending ratio on the brake power becomes weak. With the load decreasing to less than medium (50%), the specific fuel consumption increases rapidly. Also, the indicated thermal efficiency (ITE) and NOx emission per unit power, usually has an optimal value at medium load. It was shown that the ethanol content under different loading conditions should be set up reasonably. From the practicality and reliability of the simulation results, it is expected that the future will be used for the performance prediction and the optimal design of the diesel-ethanol dual-fuel engine at different loads using the two phase combustion model of GT-Power.

| Published in | International Journal of Fluid Mechanics & Thermal Sciences (Volume 11, Issue 4) |

| DOI | 10.11648/j.ijfmts.20251104.12 |

| Page(s) | 76-87 |

| Creative Commons |

This is an Open Access article, distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution and reproduction in any medium or format, provided the original work is properly cited. |

| Copyright |

Copyright © The Author(s), 2025. Published by Science Publishing Group |

Ethanol Content, Different Load, Gt-Power, Two Phase Combustion, Compression Ignition Engine

Fuel specification | unit | diesel | ethanol |

|---|---|---|---|

Molecular formula | - | C14H30 | C2H5OH |

Molecular weight | g | 198.4 | 46.068 |

Cetane number | - | 51 | 8 |

Research octane number | - | 15-25 | 129 |

Boiling point | K | 453-643 | 351 |

Liquid density | kg/m3 | 840 | 789 |

Lower heating value | MJ/kg | 42.5 | 26.9 |

Heat of evaporation | kJ/kg | 243 | 918 |

Self-ignition temperature | K | 503 | 698 |

Stoichiometric air-fuel ratio | - | 14.6 | 9.06 |

Viscosity (at 25°C) | mPa s | 2.419 | 1.078 |

Carbon content | % | 85 | 52.2 |

Hydrogen content | % | 15 | 13 |

Oxygen content | % | 0 | 34.8 |

Type | Value | Type | Value |

|---|---|---|---|

Bore × stroke (mm) | 190/210 | Compression ratio | 14:1 |

Number of cylinders | 4 | Head temperature (K) | 553 |

Brake power (kW) | 220 | Piston temperature (K) | 423 |

Nozzle radius (mm) | 0.26 | Wall temperature (K) | 433 |

Fuel injection holes | 8 | Temperature at IVC (K) | 341 |

Cylinder Pressure (MPa) | 2.05 | Pressure at IVC (bar) | 1.97 |

Connecting rod (mm) | 410 |

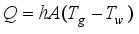

(1)

(1)  is convective heat transfer flow,

is convective heat transfer flow,  is Heat Transfer Area,

is Heat Transfer Area,  is convective heat transfer coefficient,

is convective heat transfer coefficient,  is Temperature of the cylinder wall,

is Temperature of the cylinder wall,  is gas temperature inside the cylinder.

is gas temperature inside the cylinder.  .

.  .

.  (post-combustion reaction).

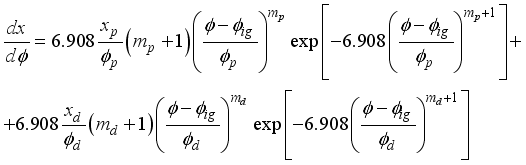

(post-combustion reaction).  (2)

(2)  are premixed-combustion duration, diffusion combustion duration,

are premixed-combustion duration, diffusion combustion duration,  are the mass fraction of burned fuel in Premixed-combustion and diffusion combustion,

are the mass fraction of burned fuel in Premixed-combustion and diffusion combustion,  are Wiebe Exponent in Premixed-combustion and diffusion combustion,

are Wiebe Exponent in Premixed-combustion and diffusion combustion,  is Instantaneous Crank Angle,

is Instantaneous Crank Angle,  is Start angle of combustion. The above equation is derived from the synthesis of two Wiebe functions, assuming that Premixed-combustion and diffusion combustion occur simultaneously. The figure shows the multi-stage Wiebe combustion input window in GT.

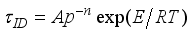

is Start angle of combustion. The above equation is derived from the synthesis of two Wiebe functions, assuming that Premixed-combustion and diffusion combustion occur simultaneously. The figure shows the multi-stage Wiebe combustion input window in GT.  (3)

(3)  (4)

(4) CN | Cetane Number |

HC | Hydrocarbons |

BD | Burn Duration |

BTE | Brake Thermal Efficiency |

HR | Heat Release |

HRR | Heat Release Rate |

ITE | Indicated Thermal Efficiency |

ID | Ignition Delay |

IMEP | Indicated Mean Effective Pressure |

TDC | Top Dead Centre |

| [1] | Hosseinzadeh-Bandbafha H, Rafee S, Mohammadi P et al, Exergetic, economic, and environmental life cycle assessment analyses of a heavy-duty tractor diesel engine fueled with diesel-biodiesel-bioethanol blends, Energy Conversion and Management 241(2021) 114300 |

| [2] | Ning Le, Duan Q, Chen Z, Kou H, Liu B, Yang Bo, Zeng Ke. A comparative study on the combustion and emissions of a non-road common rail diesel engine fueled with primary alcohol fuels (methanol, ethanol, and n-butanol)/diesel dual fuel. Fuel 2020; 266: 117034. |

| [3] | Andrew David Mendes Guedes, Sergio Leal Braga, Florian Pradelle, Performance and combustion characteristics of a compression ignition engine running on diesel-biodiesel-ethanol (DBE) blends - Part 2: Optimization of injection timing, Fuel 225(2018) 174-183. |

| [4] | Lijiang Wei, Chunde Yao, Guopeng Han, Wang Pan, Effects of methanol to diesel ratio and diesel injection timing on combustion, performance and emissions of a methanol port premixed diesel engine, Energy 95(2016) 223-232. |

| [5] | S. Saravanan, G. Nagarajan, G. Lakshmi Narayana Rao, S. Sampath, Theoretical and experimental investigation on effect of injection timing on NOx emission of biodiesel blend, Energy 66(2014) 216-221, |

| [6] | Ajav EA, Singh B, Bhattacharya TK. Experimental study of some performance parameters of a constant speed stationary diesel engine using ethanol-diesel blends as fuel. Biomass Bioenergy 1999; 17: 357-65. |

| [7] | Lapuerta M, Armas O, García-Contreras R. Stability of diesel-bioethanol blends for use in diesel engines. Fuel 2007; 86(10-11): 1351-7. |

| [8] | Agarwal AK. Biofuels (alcohols and biodiesel) applications as fuels for internal combustion engines. Prog Energy Combust Sci 2007; 33: 233-71. |

| [9] | Huang J, Wanga Y, Li S, Roskilly AP, Yu H, Li H. Experimental investigation on the performance and emissions of a diesel engine fuelled with ethanol-diesel blends. Appl Therm Eng 2009; 29: 2484-90. |

| [10] | Sahin Z, Durgun O. Prediction of the effects of ethanol-diesel fuel blends on diesel engine performance characteristics, combustion, exhaust emissions, and cost. Energy Fuels 2009; 23: 1707-17. |

| [11] | Yahuza I1 and Dandakouta H, A Performance Review of Ethanol-Diesel Blended Fuel Samples in Compression-Ignition Engine, J Chem Eng Process Technol 2015, 6: 5. |

| [12] | Gonca G. Investigation of the effects of steam injection on performance and NO emissions of a diesel engine running with ethanol-diesel blend. Energy Convers Manage 2014; 77: 450-7. |

| [13] | Sayin, C. Engine performance and exhaust gas emissions of methanol and ethanol-diesel blends. Fuel 2010, 89, 3410-3415, |

| [14] | Gnanamoorthi V, Devaradjane G. Effect of compression ratio on the performance, combustion and emission of DI diesel engine fueled with ethanol - diesel blend. J Energy Inst 2015; 88: 19-26. |

| [15] | Xing-cai L, Jian-guang Y, Wu-gao Z, Zhen H. Effect of cetane number improver on heat release rate and emissions of high speed diesel engine fueled with ethanol-diesel blend fuel. Fuel 2004; 83: 2013-20. |

| [16] | Rakopoulos CD, Antonopoulos KA, Rakopoulos DC. Experimental heat release analysis and emissions of a HSDI diesel engine fueled with ethanol-diesel fuel blends. Energy 2007; 32: 1791-808. |

| [17] | Torres-Jimenez E, Svoljšak Jerman M, Gregorc A, Lisec I, Dorado MP, Kegl B. Physical and chemical properties of ethanol-diesel fuel blends. Fuel 2011; 90: 795-802. |

| [18] | Alberto Boretti, Advantages of converting Diesel engines to run as dual fuel ethanol-Diesel, Applied Thermal Engineering 47(2012) 1-9. |

| [19] | Fadila Maroteaux, Charbel Saad, Diesel engine combustion modeling for hardware in the loop applications: Effects of ignition delay time model, Energy 57(2013) 641-52, |

| [20] | Wojciech Tutak, Kristóf Lukács, Stanisław Szwaja, Ákos Bereczky, Alcohol-diesel fuel combustion in the compression ignition engine, Fuel 154(2015) 196-206, |

| [21] | Oliveira A, Morais AM, Valente OS, Sodré JR. Combustion characteristics, performance and emissions from a diesel power generator fuelled by B7- ethanol blends. Fuel Process Technol 2015; 139: 67-72. |

| [22] | Li D, Zhen H, Xingcai L, Wu-gao Z, Jian-guang Y. Physico-chemical properties of ethanol-diesel blend fuel and its effect on performance and emissions of diesel engines. Renew Energy 2005; 30: 967-76. |

| [23] | Hubert Kuszewski, Experimental investigation of the effect of ambient gas temperature on the autoignition properties of ethanol-diesel fuel blends, Fuel 214(2018) 26-38, |

| [24] | Liu J, Li G, Liu S. Influence of ethanol and Cetane Number (CN) improver on the ignition delay of a direct-injection diesel engine. Energy Fuels 2011; 25: 103-7. |

| [25] | Jamrozik A. The effect of the alcohol content in the fuel mixture on the performance and emissions of a direct injection diesel engine fueled with diesel-methanol and diesel-ethanol blends. Energy Convers Manage 2017; 148: 461-76. Https://doi.org/10.1016/j.enconman.2017.06.030 |

| [26] | Jamrozik A. Study on co-combustion of diesel fuel with oxygenated alcohols in a compression ignition dual-fuel engine, Fuel 221(2018) 329-345. |

| [27] | Lei J, Shen L, Bi Y, Chen H. A novel emulsifier for ethanol-diesel blends and its effect on performance and emissions of diesel engine. Fuel 2012; 93: 305-11. |

| [28] | Van Basshuysen Richard, Schäfer Fred, Internal Combustion Engine Handbook. Basics, components, system and perspectives. SAE International; 2004. |

| [29] | Kidoguchi Y, Yang Ch, Kato R, Miwa K. Effects of fuel cetane number and aromatics on combustion process and emissions of a direct-injection diesel engine. JSAE Rev 2000; 21: 469-75. |

| [30] | Taghizadeh-Alisaraei A, Rezaei-Asl A. The effect of added ethanol to diesel fuel on performance, vibration, combustion and knocking of a CI engine. Fuel 2016; 185: 718-33. |

| [31] | Rakopoulos DC, Rakopoulos CD, Kakaras EC, Giakoumis EG. Effects of ethanol-diesel fuel blends on the performance and exhaust emissions of heavy duty DI diesel engine. Energy Convers Manage 2008; 49: 3155-62. |

| [32] | Le Ning, Qimeng Duan, Hailiang Kou, Ke Zeng, Parametric study on effects of methanol injection timing and methanol substitution percentage on combustion and emissions of methanol/diesel dual-fuel direct injection engine at full load, Fuel 279(2020) 118424. |

| [33] | Murcak A, Haşimoğlu C, Çevik İ, Karabektaş M, Ergen G. Effects of ethanol-diesel blends to performance of a DI diesel engine for different injection timings. Fuel 2013; 109: 582-7. |

| [34] | Jayashankara B, Ganesan V. Effect of fuel injection timing and intake pressure on the performance of a DI diesel engine - A parametric study using CFD. Energy Convers Manage 2010; 51: 1835-48. |

| [35] | Hubert Kuszewski, Effect of adding 2-ethylhexyl nitrate cetane improver on the autoignition properties of ethanol-diesel fuel blend - Investigation at various ambient gas temperatures, Fuel 224(2018) 57-67. |

| [36] | Liu S, Zhu Z, Zhang Z, Gao G, Wei Y. Effect of a Cetane Number (cn) improver on combustion and emission characteristics of a compression-ignition (ci) engine fueled with an ethanol-diesel blend. Energy Fuels 2010; 24: 2449-54. |

| [37] | Herreros JM, Schroer K, Sukjit E, Tsolakis A. Extending the environmental benefits of ethanol-diesel blends through DGE incorporation. Appl Energy 2015; 146: 335-43. |

| [38] | Tutak, W and Arkadiusz Jamrozik, A., Comparative Analysis of Combustion Stability of Diesel/Ethanol Utilization by Blend and Dual Fuel, Processes 2019, 7, 946. |

| [39] | Zhiqiang Wang, Lijun Li, Effects of Different Ethanol/Diesel Blending Ratios on Combustion and Emission Characteristics of a Medium-Speed Diesel Engine, Processes 2022, 10, 173. |

| [40] | Praptijantoa A, Muharama A, Nura A, Putrasaria Y. Effect of ethanol percentage for diesel engine performance using virtual engine simulation tool. Energy Procedia 2015; 68: 345-54. |

| [41] | Labeckas Gvidonas, Slavinskas Stasys, Mažeika Marius. The effect of ethanol-diesel-biodiesel blends on combustion, performance and emissions of a direct injection diesel engine. Energy Convers Manage 2014; 79: 698-720. |

| [42] | Vinícius B. Pedrozo, Ian May, Macklini Dalla Nora, Alasdair Cairns, Hua Zhao Experimental analysis of ethanol dual-fuel combustion in a heavy-duty diesel engine: an optimization at low load, |

| [43] | Han, J.; Somers, L.M.T.; Cracknell, R.; Joedicke, A.; Wardle, R.; Mohan, V.R.R. Experimental investigation of ethanol/diesel dual-fuel combustion in a heavy-duty diesel engine. Fuel 2020, 275, 117867. |

| [44] | Heywood JB. Internal combustion engine fundamentals. New York: McGraw-Hill Book Company; 1988. |

| [45] | Heywood JB. Internal combustion engine fundamentals. New York: McGraw-Hill Book Company; SECOND EDITION 2018. |

| [46] | Chen, S.K., Flynn, P.F., Development of a Single Cylinder Compression Ignition Research Engine, SAE Paper 650733.1965. |

APA Style

Han, P. I., Kim, N. S., Chol, R. M., Jae, M. Y. (2025). Simulation of the Effect of Ethanol Blending Ratio on Combustion and Performance of Diesel-Ethanol Dual-Fuel Engine at Different Loads. International Journal of Fluid Mechanics & Thermal Sciences, 11(4), 76-87. https://doi.org/10.11648/j.ijfmts.20251104.12

ACS Style

Han, P. I.; Kim, N. S.; Chol, R. M.; Jae, M. Y. Simulation of the Effect of Ethanol Blending Ratio on Combustion and Performance of Diesel-Ethanol Dual-Fuel Engine at Different Loads. Int. J. Fluid Mech. Therm. Sci. 2025, 11(4), 76-87. doi: 10.11648/j.ijfmts.20251104.12

AMA Style

Han PI, Kim NS, Chol RM, Jae MY. Simulation of the Effect of Ethanol Blending Ratio on Combustion and Performance of Diesel-Ethanol Dual-Fuel Engine at Different Loads. Int J Fluid Mech Therm Sci. 2025;11(4):76-87. doi: 10.11648/j.ijfmts.20251104.12

@article{10.11648/j.ijfmts.20251104.12,

author = {Phyong Il Han and Nam Su Kim and Ri Myong Chol and Min Yong Jae},

title = {Simulation of the Effect of Ethanol Blending Ratio on Combustion and Performance of Diesel-Ethanol Dual-Fuel Engine at Different Loads

},

journal = {International Journal of Fluid Mechanics & Thermal Sciences},

volume = {11},

number = {4},

pages = {76-87},

doi = {10.11648/j.ijfmts.20251104.12},

url = {https://doi.org/10.11648/j.ijfmts.20251104.12},

eprint = {https://article.sciencepublishinggroup.com/pdf/10.11648.j.ijfmts.20251104.12},

abstract = {The use of ethanol in diesel engines as an alternative to fossil fuels and air pollution prevention due to vehicle exhaust emissions has been investigated. It can be seen that for a more practical application of the performance study of diesel-ethanol dual fuel engine, the effect of ethanol on the performance at 100% load as well as at different load conditions should be considered. The effect of ethanol content on combustion and performance characteristics under different load conditions of diesel-ethanol dual-fuel engine was investigated using engine simulation tool. The engine model was constructed using the pre-combustion-diffusion combustion two phase combustion model of GT-POWER, and the simulation results of the main performance indices were compared with the test data. The effect of ethanol blending ratio on the performance of diesel-ethanol blend engine with varying ethanol content (0-20% ethanol) under different loading conditions (25-100% load) was investigated. As the load decreases, the effect of ethanol blending ratio on the brake power becomes weak. With the load decreasing to less than medium (50%), the specific fuel consumption increases rapidly. Also, the indicated thermal efficiency (ITE) and NOx emission per unit power, usually has an optimal value at medium load. It was shown that the ethanol content under different loading conditions should be set up reasonably. From the practicality and reliability of the simulation results, it is expected that the future will be used for the performance prediction and the optimal design of the diesel-ethanol dual-fuel engine at different loads using the two phase combustion model of GT-Power.

},

year = {2025}

}

TY - JOUR T1 - Simulation of the Effect of Ethanol Blending Ratio on Combustion and Performance of Diesel-Ethanol Dual-Fuel Engine at Different Loads AU - Phyong Il Han AU - Nam Su Kim AU - Ri Myong Chol AU - Min Yong Jae Y1 - 2025/10/10 PY - 2025 N1 - https://doi.org/10.11648/j.ijfmts.20251104.12 DO - 10.11648/j.ijfmts.20251104.12 T2 - International Journal of Fluid Mechanics & Thermal Sciences JF - International Journal of Fluid Mechanics & Thermal Sciences JO - International Journal of Fluid Mechanics & Thermal Sciences SP - 76 EP - 87 PB - Science Publishing Group SN - 2469-8113 UR - https://doi.org/10.11648/j.ijfmts.20251104.12 AB - The use of ethanol in diesel engines as an alternative to fossil fuels and air pollution prevention due to vehicle exhaust emissions has been investigated. It can be seen that for a more practical application of the performance study of diesel-ethanol dual fuel engine, the effect of ethanol on the performance at 100% load as well as at different load conditions should be considered. The effect of ethanol content on combustion and performance characteristics under different load conditions of diesel-ethanol dual-fuel engine was investigated using engine simulation tool. The engine model was constructed using the pre-combustion-diffusion combustion two phase combustion model of GT-POWER, and the simulation results of the main performance indices were compared with the test data. The effect of ethanol blending ratio on the performance of diesel-ethanol blend engine with varying ethanol content (0-20% ethanol) under different loading conditions (25-100% load) was investigated. As the load decreases, the effect of ethanol blending ratio on the brake power becomes weak. With the load decreasing to less than medium (50%), the specific fuel consumption increases rapidly. Also, the indicated thermal efficiency (ITE) and NOx emission per unit power, usually has an optimal value at medium load. It was shown that the ethanol content under different loading conditions should be set up reasonably. From the practicality and reliability of the simulation results, it is expected that the future will be used for the performance prediction and the optimal design of the diesel-ethanol dual-fuel engine at different loads using the two phase combustion model of GT-Power. VL - 11 IS - 4 ER -